Optimizing the World's Hydromet Facilities

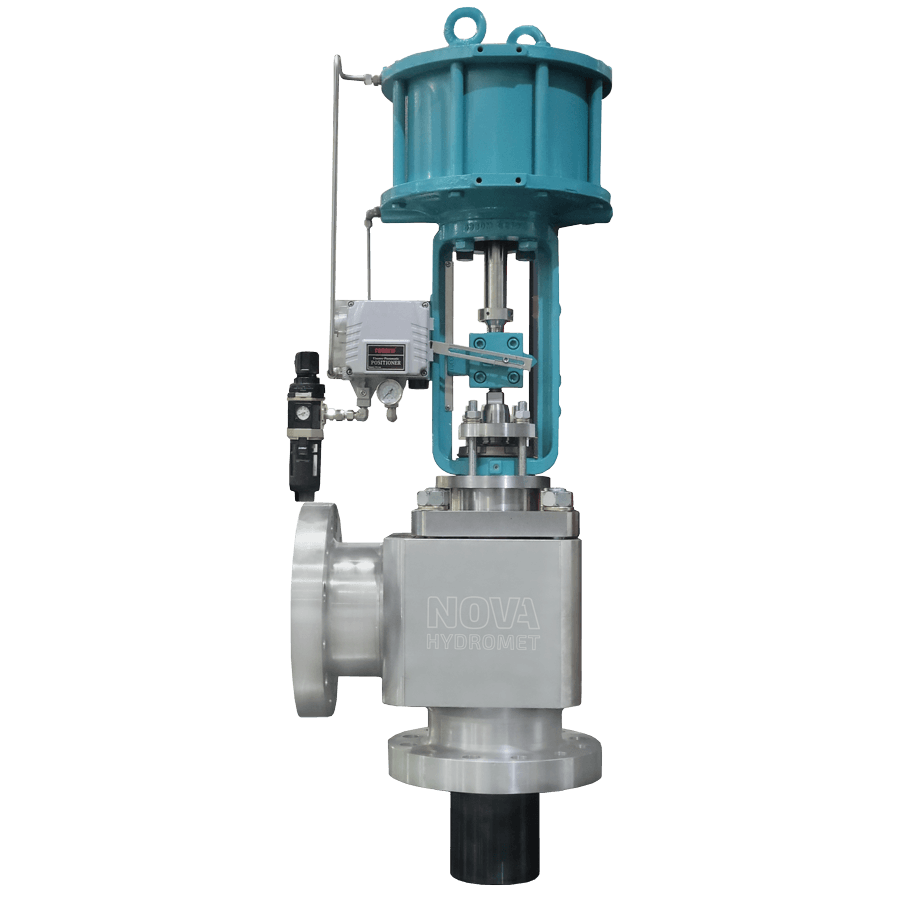

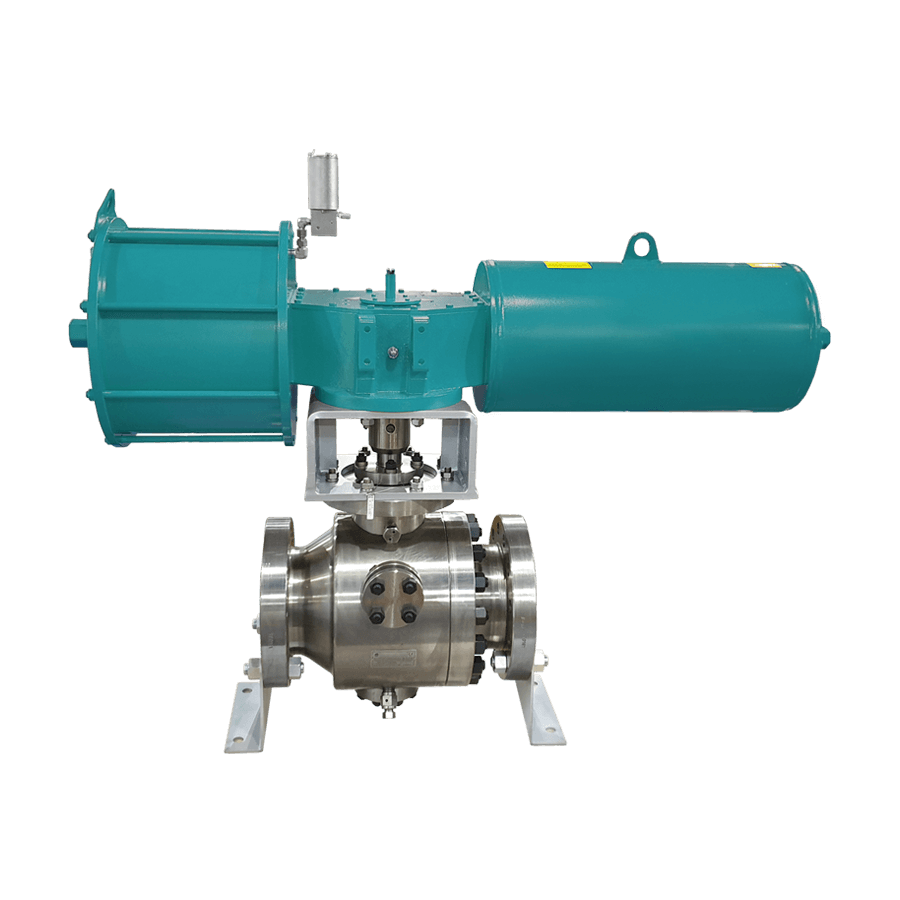

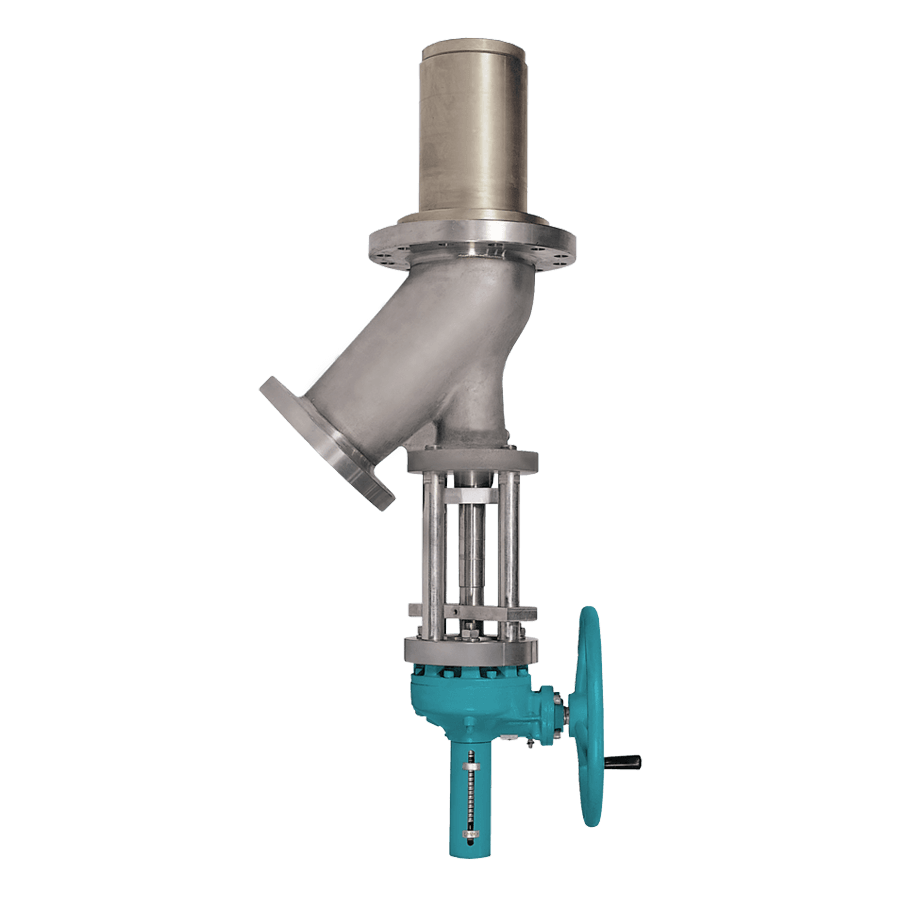

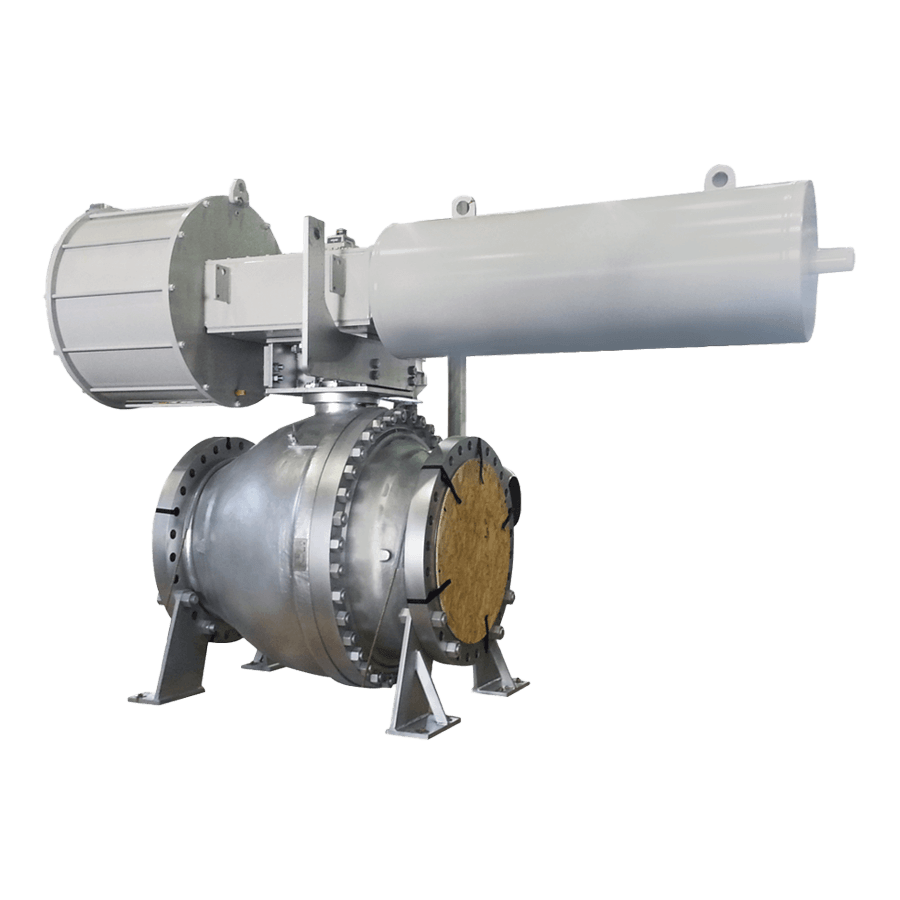

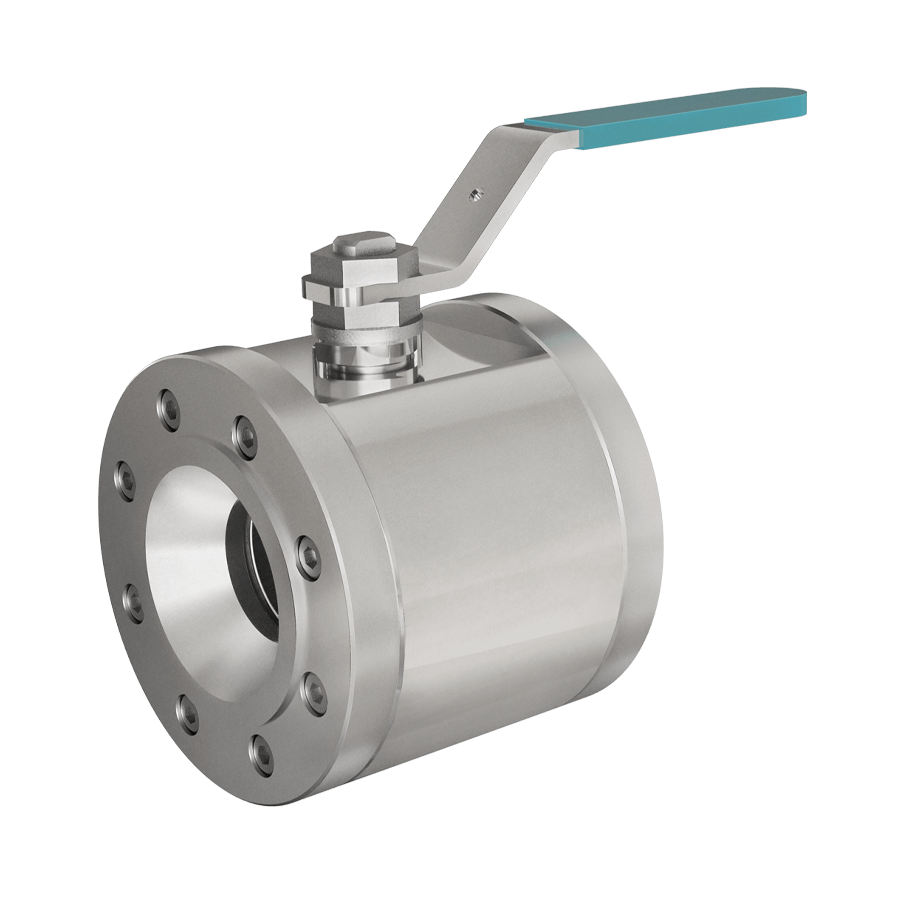

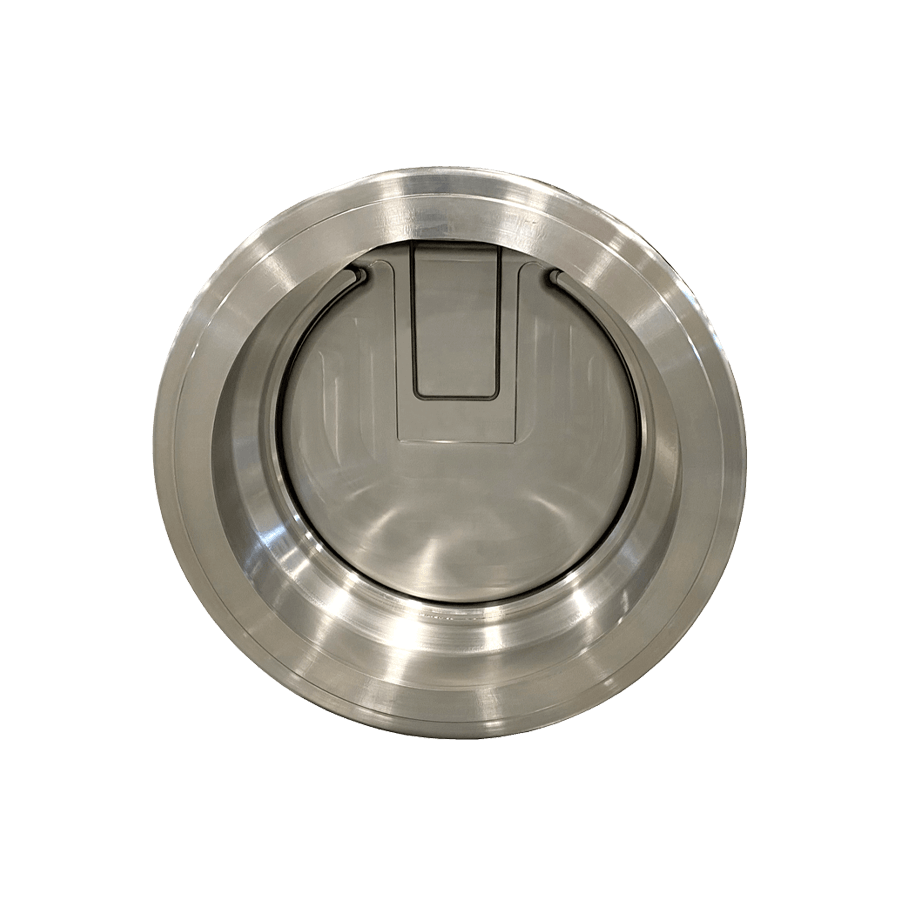

Severe Service Equipment

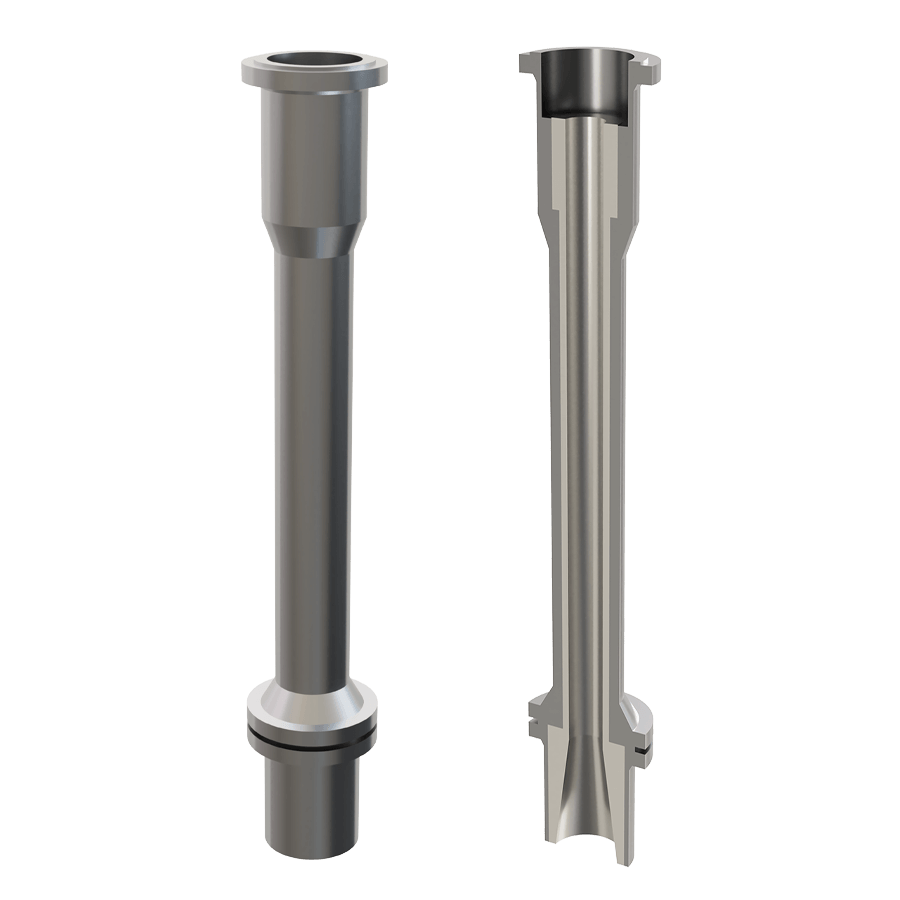

Letdown Service Equipment

Manufacturing Capability

Casting & Forging |

Technical ceramics & cermets |

Coatings & overlays |

Electron beam welding

Repair & Servicing

Authorized Service Centres

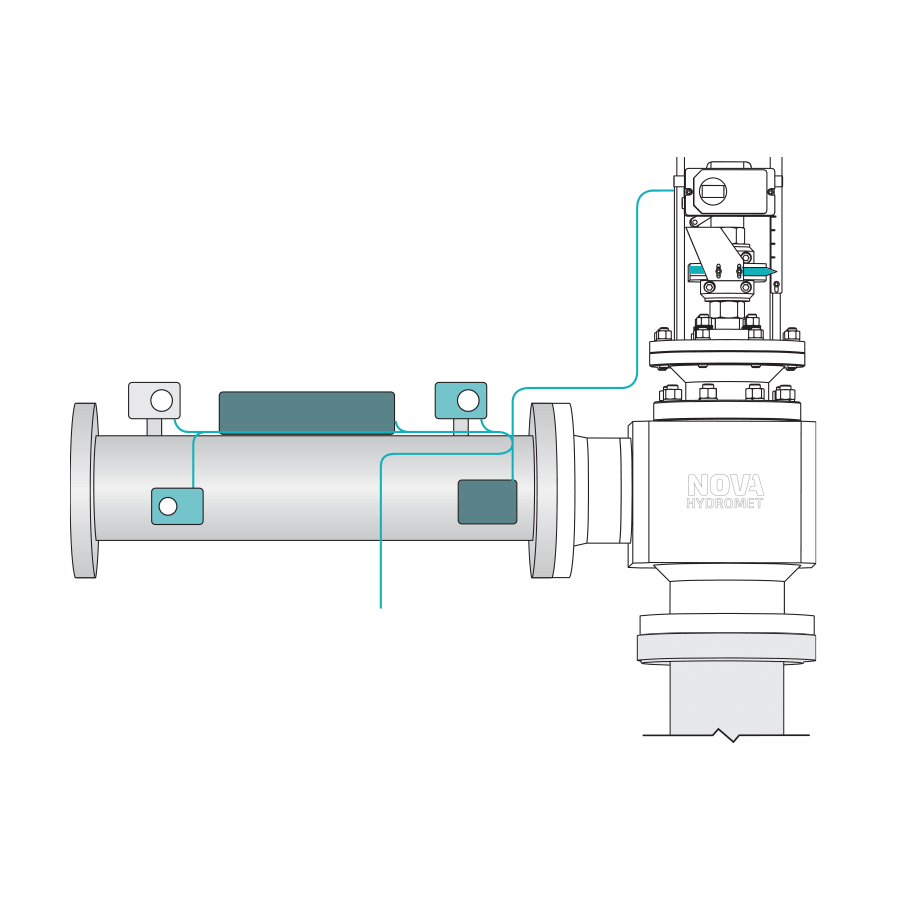

A Holistic Approach to Autoclave Systems

Inherently complex autoclave systems need holistic science-based solutions to help increase yield, reduce downtime, and decrease costs from failed equipment.

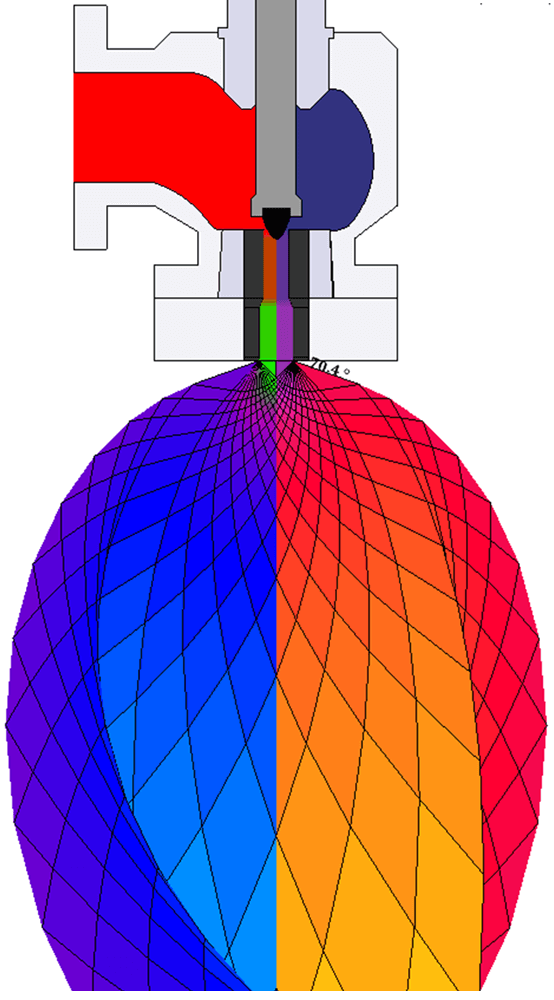

Incorrectly sized letdown components can cause costly performance issues, but NOVA ensures optimal flow and velocity by properly sizing all key elements—from inlet and outlet lines to control valve trims and blast tubes.

NOVA uses fluid flow modelling to analyze velocity, pressure, and kinetic energy across all flow ranges to accurately assess erosive potential and determine the correct seat size for each angle control valve.

NOVA uses classical process analysis—including mass and energy balancing and reaction kinetics modeling—to optimize autoclave performance, simulate operating procedures, and maximize ore yield.