Optimize Your Plant with SAM GUARD®

Improved reliability.

Gains in production.

Reduced costs and downtime.

AI-Powered Software

Human-enhanced machine learning software that detects equipment failures and process deviations in the very early stages, well before human or DCS Alerts.

Features include:

- AI-powered early alerts: prepare a plan of action, long before the discovered issues have a significant impact on your plant. The earlier you detect a failure, the less it costs to repair it and the equipment is most often still recoverable.

- Unsupervised and supervised AI: ensure that you receive alerts on known or repeating issues in addition to discovering unknown issues without human guidance.

- Data security: SAM GUARD® is ISO 27001 certified and can be hosted on-site or in the cloud.

Human-Enhancement Continuous Monitoring

- AI-powered early alerts: prepare a plan of action, long before the discovered issues have a significant impact on your plant. The earlier you detect a failure, the less it costs to repair it and the equipment is most often still recoverable.

- Unsupervised and supervised AI: ensure that you receive alerts on known or repeating issues in addition to discovering unknown issues without human guidance.

- Data security: SAM GUARD® is ISO 27001 certified and can be hosted on-site or in the cloud.

How the Software Works

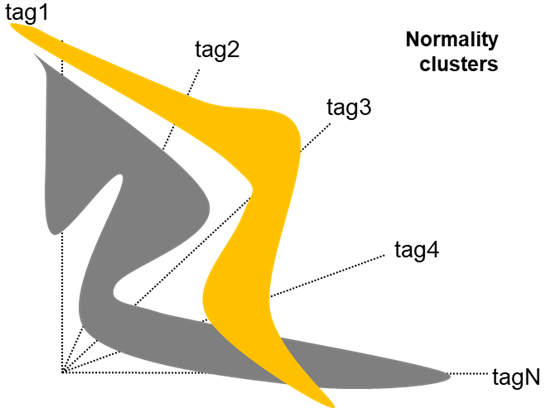

We create a Digital Twin of your plant in the software, mapping all relationships between data tags and the process.

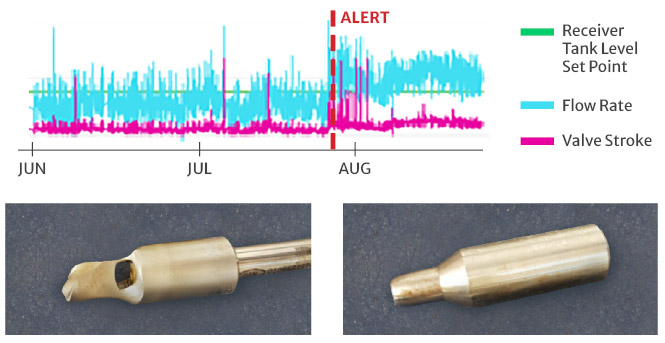

Use Case 1

Use Case 2

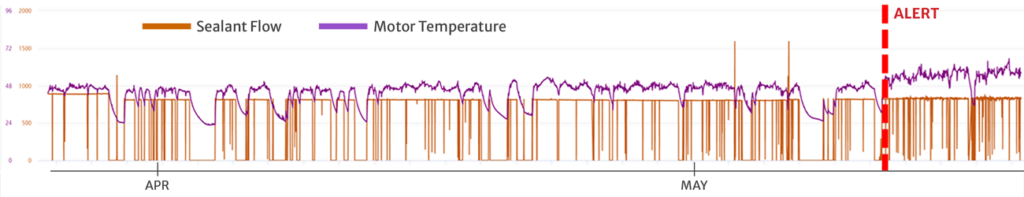

At a remote piece of mining equipment, SAM GUARD® detected a leak in a sealant line long before anyone would have been physically present to notice.

SAM GUARD® detects failures before process parameters exceed single variable upper or lower control limits by monitoring multi-variate norms – in this case sealant flow and motor temperature.

About SAM GUARD®

SAM GUARD® is a software and service solution developed by Precognize, a SAMSON company. Precognize is an innovative AI company honored as a Technology Pioneer by the World Economic Forum in 2018.

NOVA Hydromet is the official distributor of SAM GUARD® software for pressure hydrometallurgy facilities worldwide.