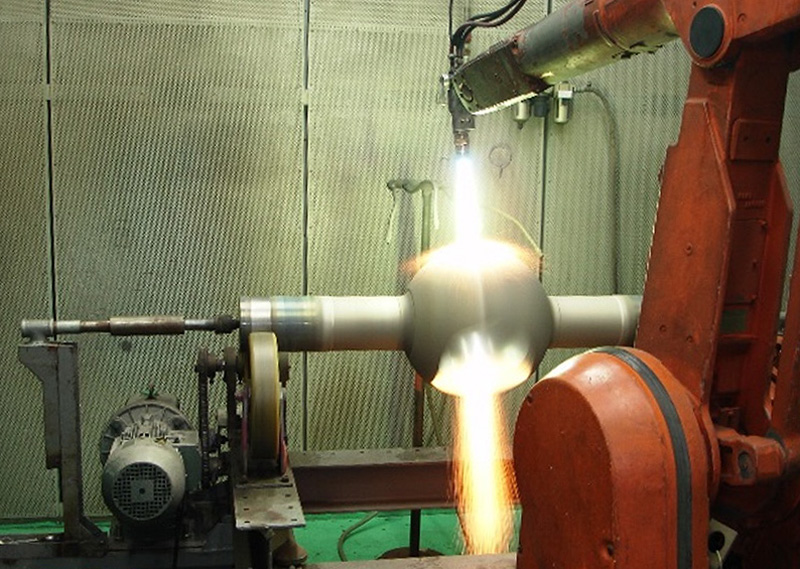

High Velocity Oxygen Fuel (HVOF) Coatings

NOVA can supply specialty hard coatings for severe service balls, seats, and valve bores. NOVA’s manufacturing team works with a trusted third party to provide this specialized service.

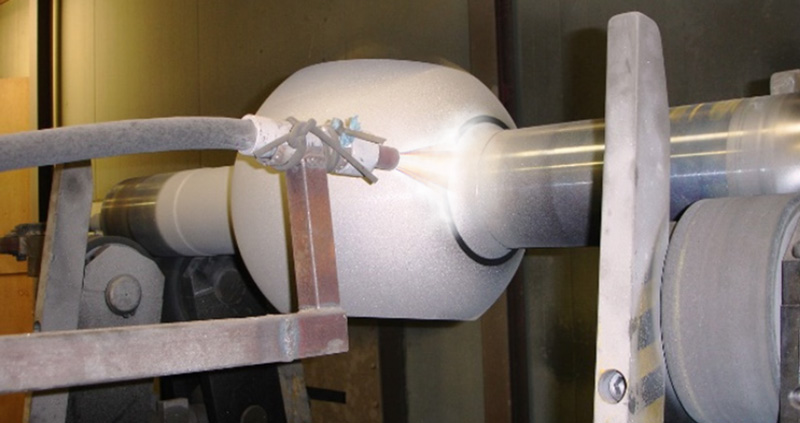

The key parameters for robust coatings are porosity and bond strength. For highly acidic applications with Titanium valve components, NOVA generally recommends a Titanium Dioxide coating, which research has shown to be less prone to corrosion and spalling.

For non-acidic applications, Tungsten Carbide coatings over stainless or carbon steel base metal can be a good option. Depending on the application, NOVA can also provide a Chrome Carbide coating.

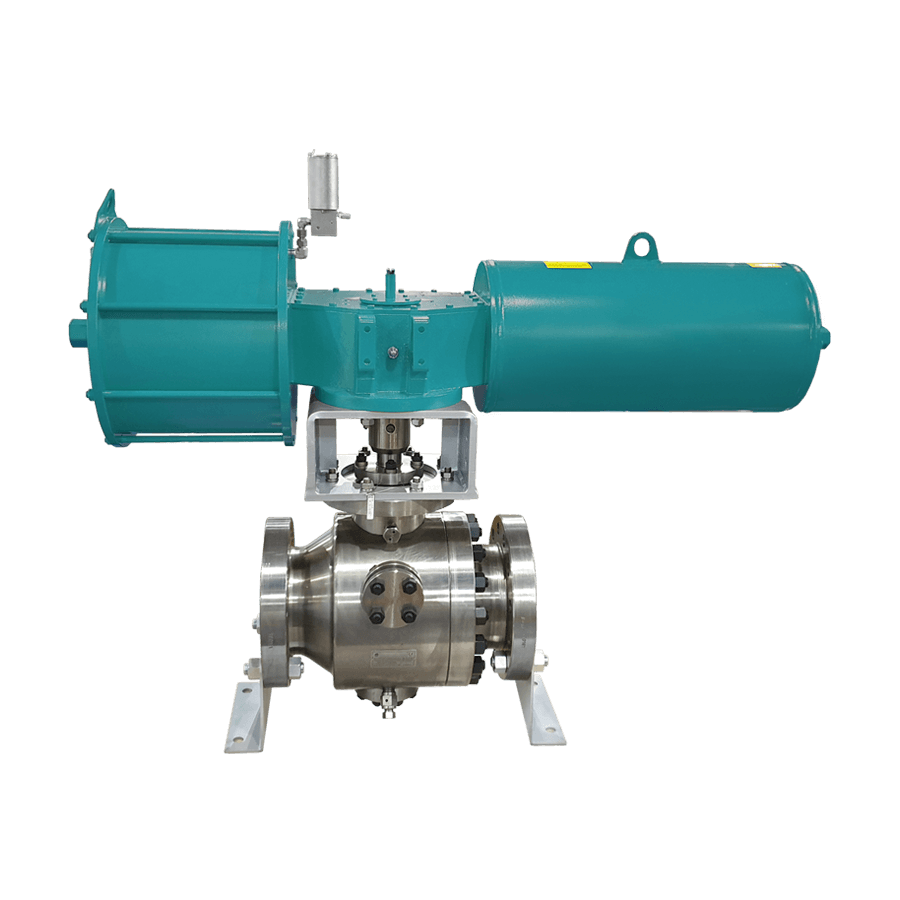

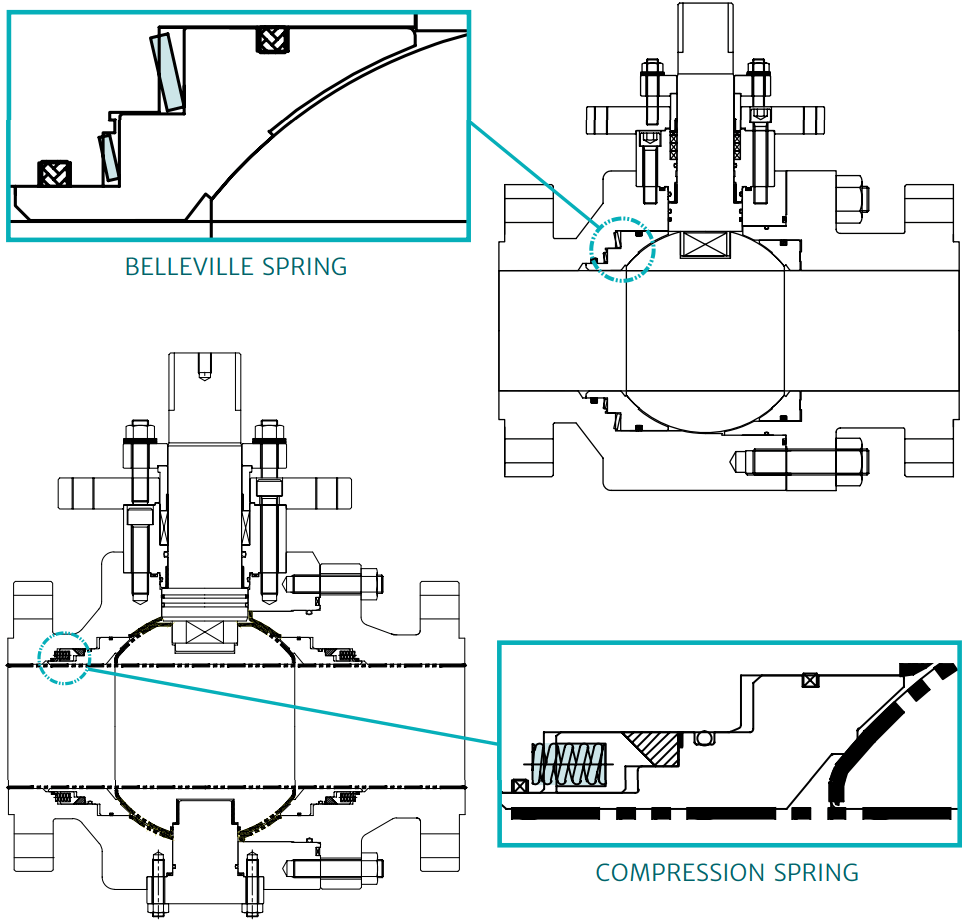

Live Loaded Seat Options

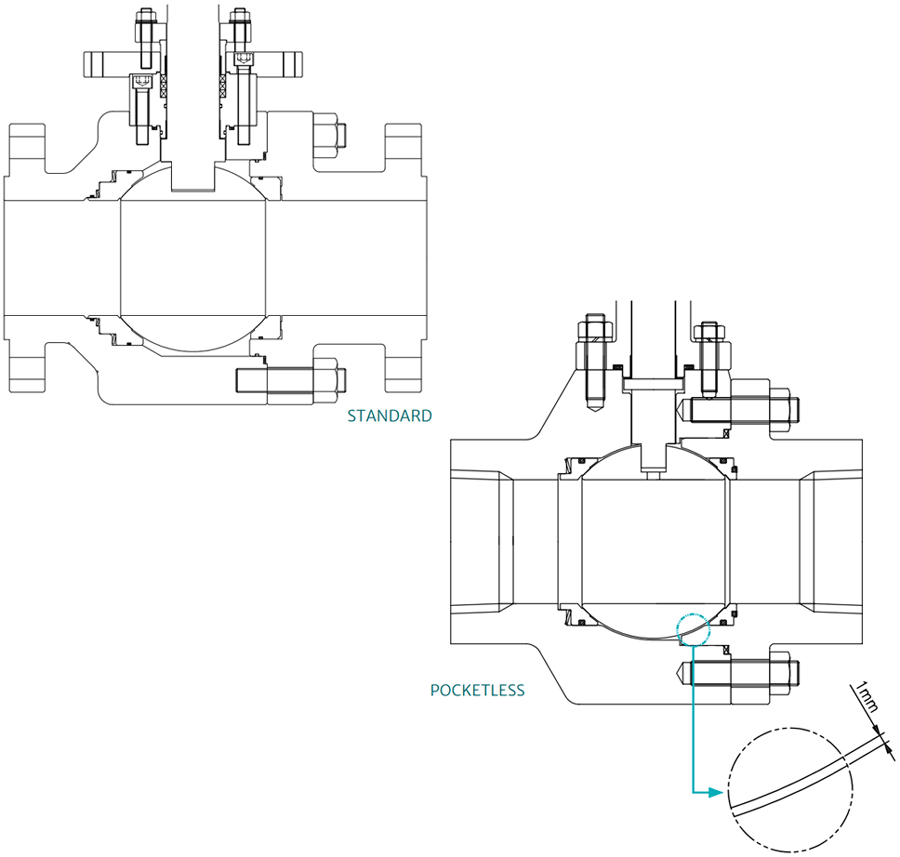

Standard vs. Pocketless Design

NOVA’s Severe Service Ball Valve has a pocketless design not found in other similar valves. The valve body components are machined to match closely with the ball, usually a gap of about 1 mm for smaller sizes and slightly larger for large diameter valves. Minimizing the gap between the ball and body leaves less space for process to accumulate or scale to build up. A standard design is also available.