Design Review

The earlier in the design process that we can give input, the better — as early as pre-feasibility.

NOVA Hydromet’s team can help prevent problems at your site before they occur. Our design review service will have our controls, process, and product experts reviewing your plans for new plant design, plant expansion, or process changes.

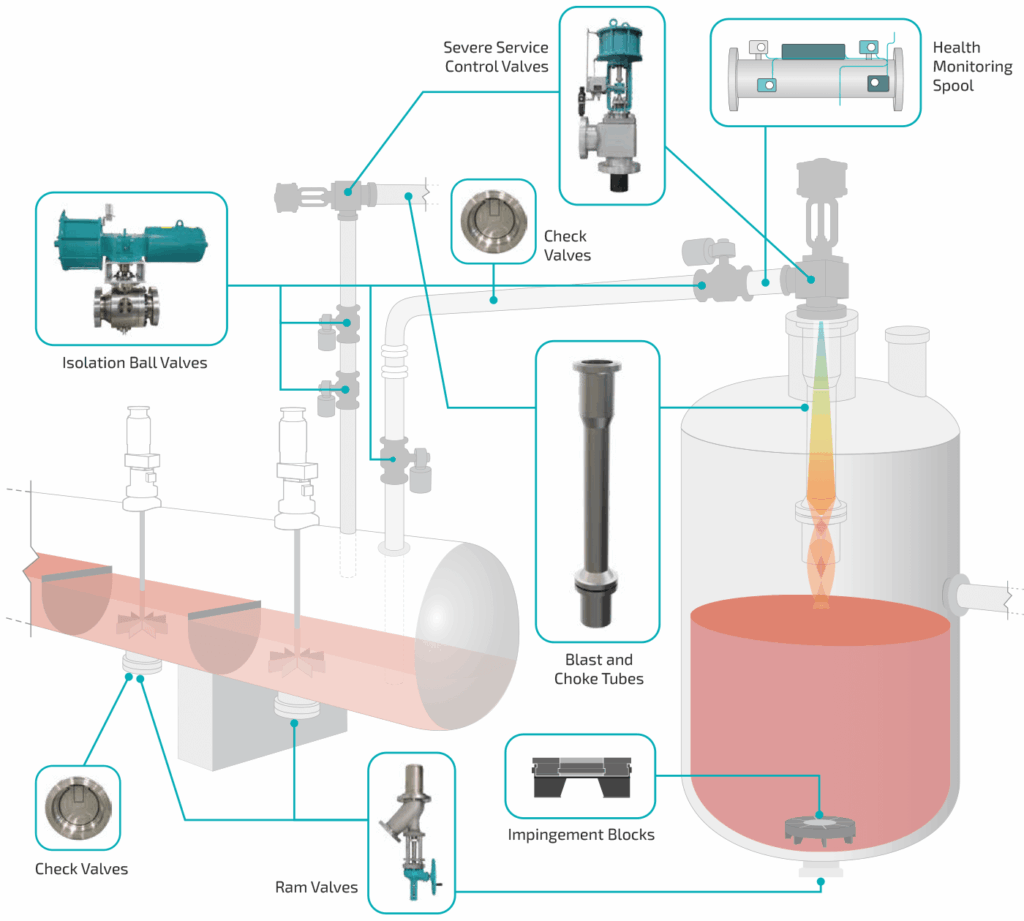

Letdown System Sizing

Letdown Flow Modelling

Control Philosophy

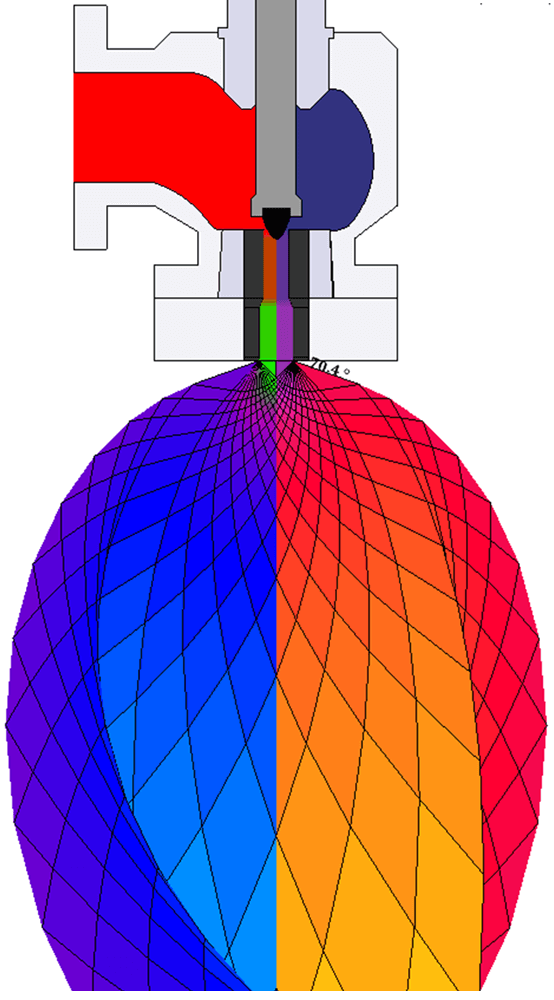

Control philosophy for letdown systems should consider the counterintuitive flow characteristics of multiphase flashing flow. Certain operating regimes can be particularly damaging, even at low flows. NOVA can help extend equipment life and prevent unscheduled downtime by recommending a bespoke control philosophy for each letdown system, based on quantitative mathematical modeling results.

Process Analysis

NOVA performs classical process analysis to balance and optimize autoclave reaction performance. Mass and Energy Balancing allows simulation of startup and shutdown procedures and forecasts autoclave temperature. Reaction Kinetics modeling helps optimize reactant inputs and overpressure to get the highest ore yield.

Root Cause Analysis

Our subject matter experts have experience triaging hundreds of broken components using a multi-disciplinary approach, including fracture mechanics, multiphase flow theory, operating data analytics, and physical inspections.

In addition to root cause analysis for discrete failures, we can help your site track the lifecycle of problem components to help quantify component life trends and improvements.

System Modelling

A disciplined scientific approach to resolving systemic throughput issues.

Systemic issues in autoclave operation, such as restricted throughput or consistent poor equipment life, will benefit from physics-based modelling.

NOVA's physics-based models take the guesswork out of predicting how your autoclave systems will function under a given set of parameters. Our team can assist by creating models that mirror the specific setup and physics of your autoclave systems.

The models act as digital twins which can then be used to train personnel on how your process functions, run what-if scenarios for predicting autoclave behavior, and troubleshoot control issues. All with the goal of optimizing production.